Wooden WPC Door Manufacturer

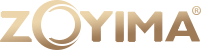

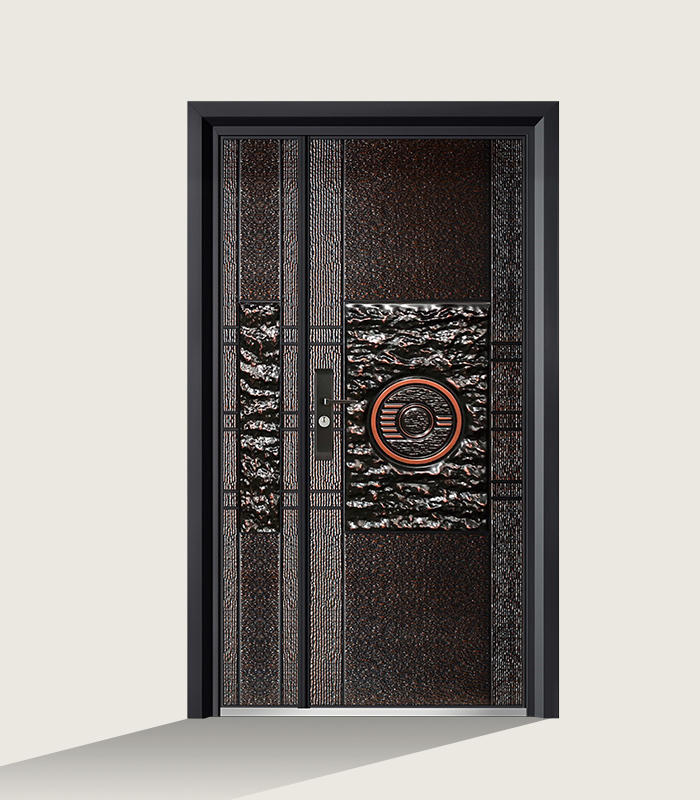

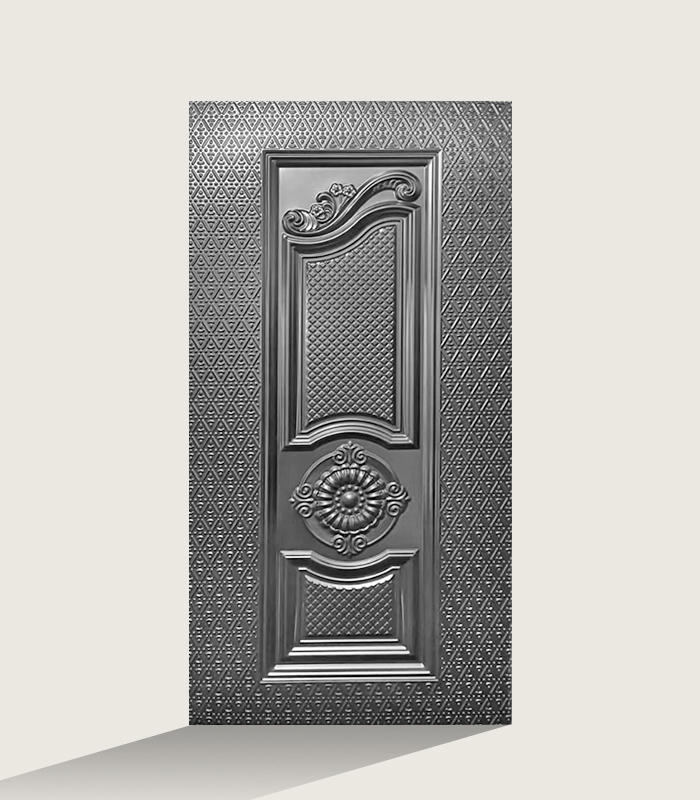

1. The materials of the wooden door are solid wood board style, reinforced board style, (thickness 8mm, filled with wooden frame tempered board), door leaf thickness 40-45mm; hinge is 3mm precision cast hinge, ordinary copper lock cylinder, simple door handle, Silent windproof door strips are adopted;

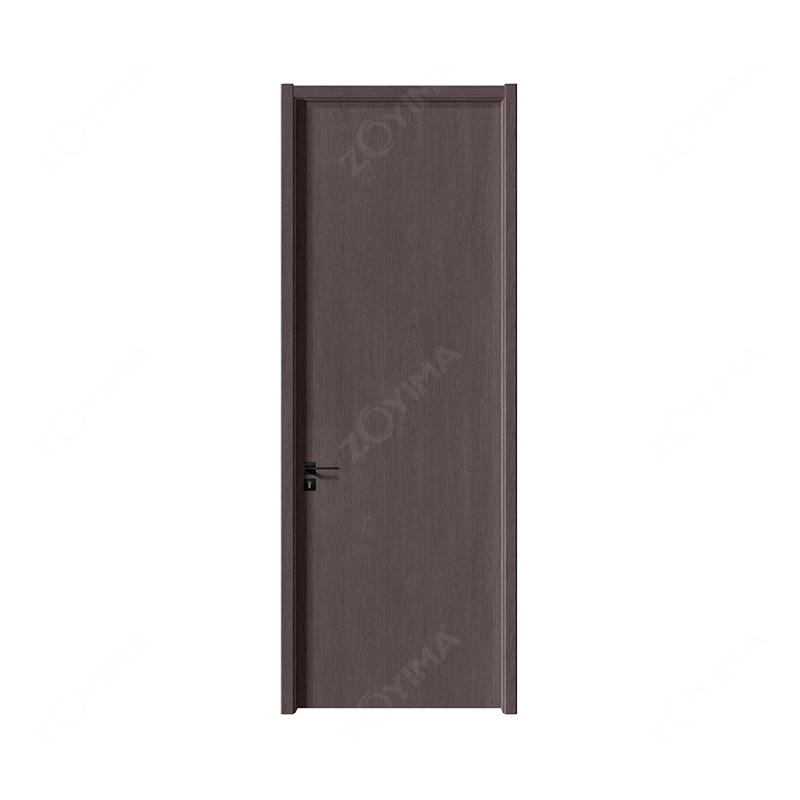

2. Suitable for indoor door installation, suitable for any country, Asia, Middle East, Oceania, Europe, America, and Africa, with modern style, European and American style, Nordic style, retro style, simple style, and other styles, wooden doors let you have a warm feeling sense of home;

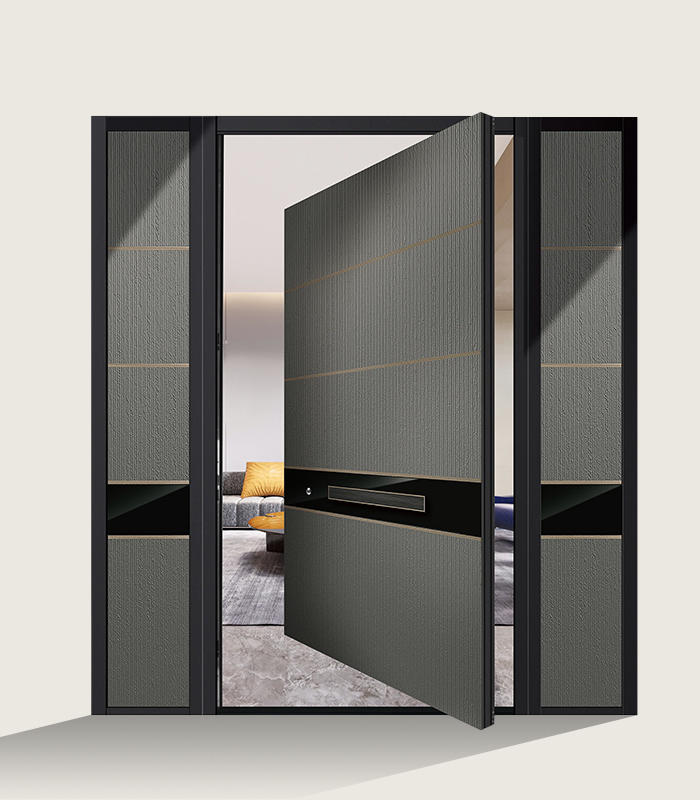

3. The wooden door adopts high-end door paint. The door surface is polished and painted by hand for many times and then dried naturally to ensure that the wooden door texture is fine or smooth. After the surface is completed, locks, hinges, and door frames are assembled. According to multiple anti-theft tests, the wooden door is graded A, B, C, D;

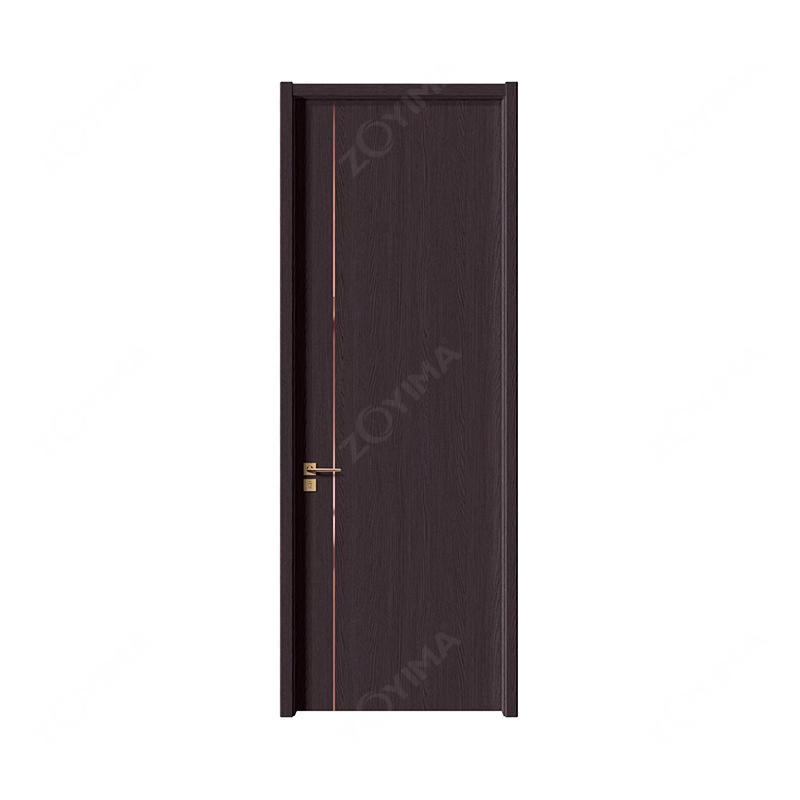

4. Wooden door paint is environmentally friendly, scratch-resistant, anti-corrosion, wear-resistant, and anti-oxidation, and does not peel off the paint. It has artistic beauty and a noise-reduction effect. It adopts the principle of magnetic opening and closing to reduce the collision between the deadbolt and the door frame, and the mute strip blocks the sound. The transmission track allows you to enjoy a quiet and comfortable home; the hidden lock tongue reduces the sound of physical impact, and at the same time reduces scratches on clothes, avoiding the hands of family members, giving you peace of mind while enjoying a quiet home;

5. The solid wood door is moisture-proof, wear-resistant, heat-resistant, and impact-resistant. The solid wood is filled with anti-deformation. It can be used for lines, carvings, and inlaid metal lines. Different aesthetic designs present different styles and styles, advanced design concepts, and a sense of fashion. The material of the wooden door determines the weight of the door, any style and size can be customized;

6. The innermost layer of the transportation package is a bubble bag, and the outer layer is packed in a carton to avoid violent collisions and ensure that it is transported to the customer in good condition.

Advantage:

1. The door plate adopts natural solid wood, clear surface texture, moisture-proof and abrasion-resistant, scratch-resistant, and easy to clean;

2. High rebound sealing tape design is adopted between the door cover and the door fan, a small extrusion gap, and a sound insulation effect is strong;

3. The hand-carved lines are exquisite and smooth, with a variety of door panel colors for you to choose from;

4. The simple metal strip breaks with tradition, adding artistic beauty;

5. Mute the door lock, free to open the door;

6. Door Paint Health and environmental protection, install immediately, and live immediately.

Español

Español Deutsch

Deutsch عربى

عربى

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)