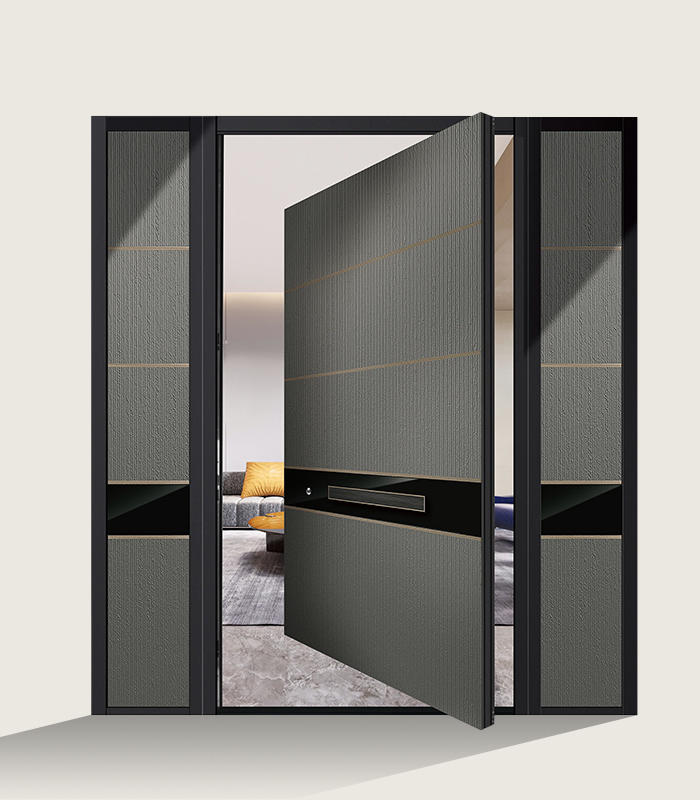

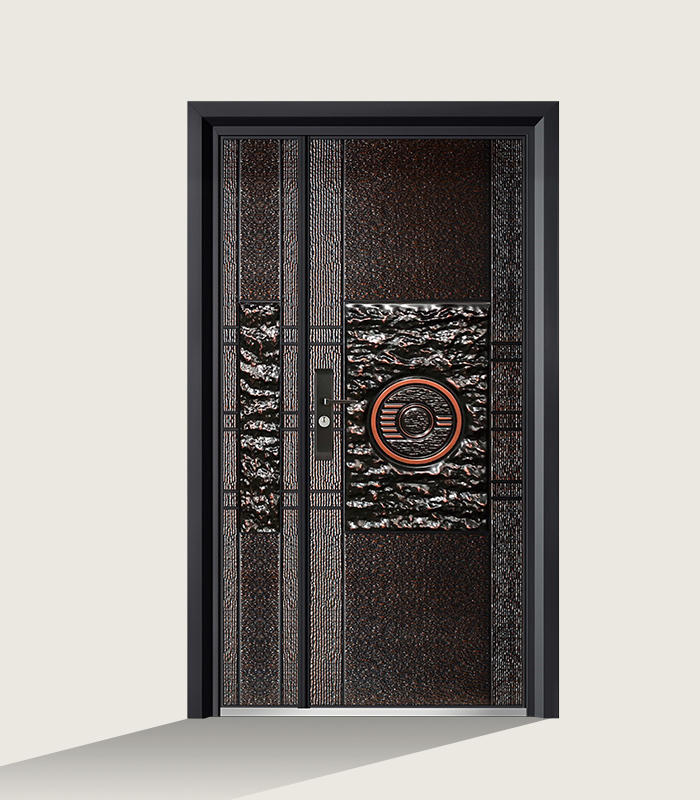

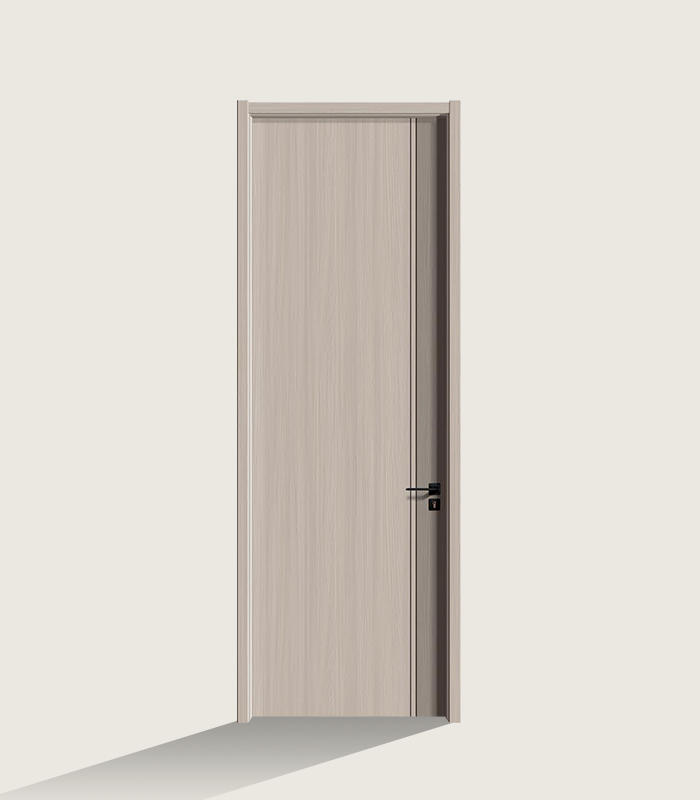

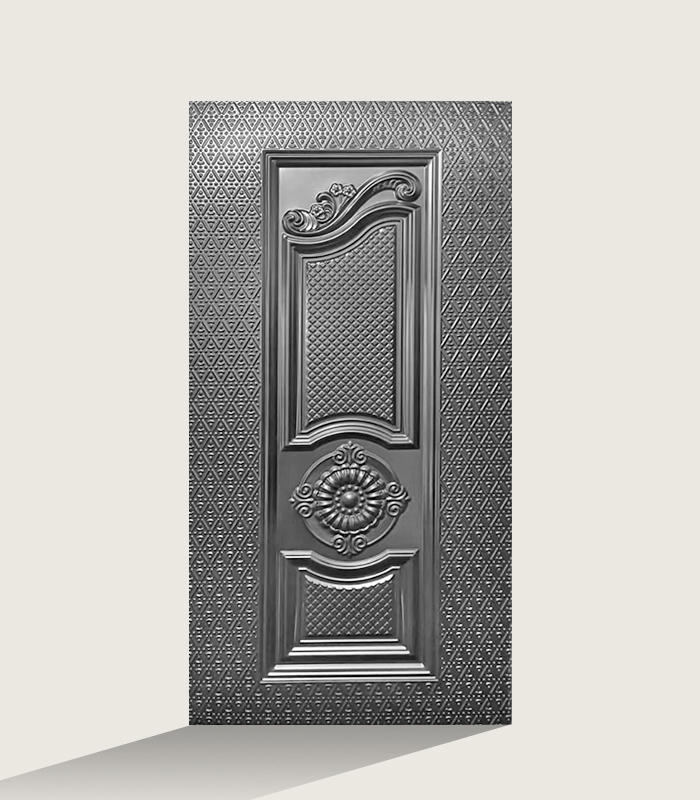

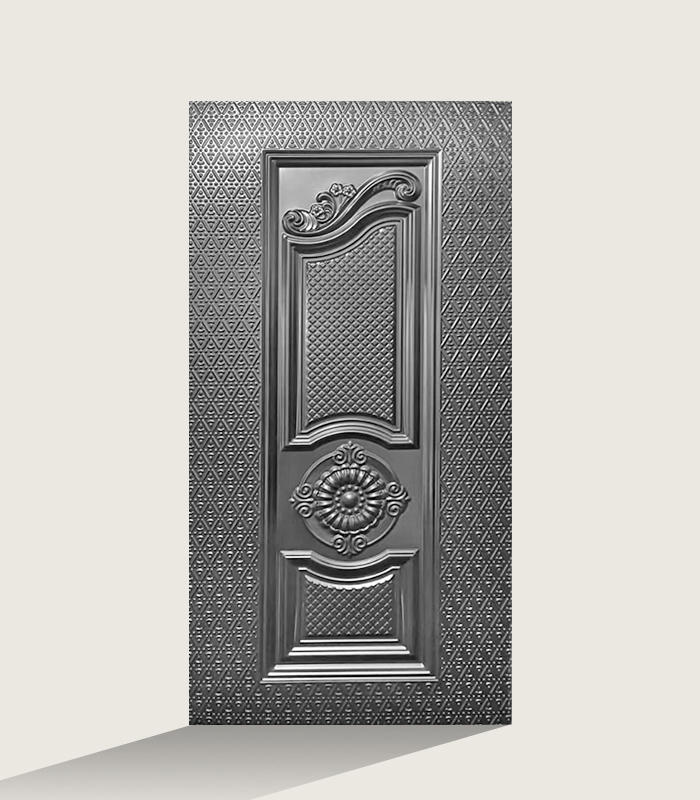

Cheap Manufacturing Cast Aluminum Doors, China Manufacturing Cast Aluminum Doors

In the world of architectural design, where form and function seamlessly converge, the manufacturing of cast aluminum doors stands as a testament to the intricate dance between craftsmanship and technology. As designers immersed in the realm of architectural elements, our journey takes us behind the scenes to unravel the meticulous process of Manufacturing Cast Aluminum Doors. This article delves into the subtle artistry, precision engineering, and collaborative efforts involved in bringing these elegant and durable doors to life.

Understanding the Intricacies of Manufacturing Cast Aluminum Doors:

At the core of architectural design lies the careful consideration of materials, and cast aluminum has emerged as a favored choice for doors that marry aesthetic appeal with durability. Manufacturing Cast Aluminum Doors involves a comprehensive process that transforms raw materials into refined architectural elements. The intricacies of this manufacturing process influence the final product's strength, resilience, and visual allure.

Casting as the Foundation:

The manufacturing journey of cast aluminum doors commences with the casting process—a method that has stood the test of time for its reliability and versatility. Aluminum, known for its lightweight yet robust properties, is melted and poured into meticulously crafted molds. The molds, designed with precision, dictate the contours, patterns, and details that will define the final door. Casting sets the foundation for the subsequent stages, laying the groundwork for both form and functionality.

Pattern Making and Mold Design:

The success of Manufacturing Cast Aluminum Doors hinges on the accuracy of pattern making and mold design. Designers, often working hand-in-hand with skilled craftsmen, create intricate patterns that serve as the prototypes for the final molds. These patterns are meticulously crafted to capture the nuances of the desired design—whether it be a classic motif, a contemporary geometric pattern, or a custom design tailored to architectural specifications.

Once the patterns are perfected, they become the basis for constructing molds. Mold design is a meticulous process that involves translating the intricacies of the pattern into a three-dimensional structure capable of withstanding the casting process. The precision of mold design is a critical factor influencing the consistency and quality of the final cast aluminum doors.

Sand Casting: An Art and Science:

Sand casting, a centuries-old technique, remains a cornerstone of manufacturing cast aluminum doors. This method involves creating a mold using compacted sand, into which molten aluminum is poured. The sand mold not only defines the external contours but also supports the intricate details and textures of the door's surface.

The artistry in sand casting lies in the skillful crafting of the sand mold to faithfully reproduce the pattern's details. Skilled artisans carefully prepare the sand mixture, create the mold, and ensure that it can withstand the intense heat of molten aluminum. The result is a door with a surface that reflects the precision and artistry inherent in the casting process.

Alloy Selection for Strength and Durability:

The choice of aluminum alloy is a critical aspect of Manufacturing Cast Aluminum Doors. Different alloys offer varying degrees of strength, corrosion resistance, and malleability. Designers, in collaboration with materials engineers, carefully select the alloy that aligns with the door's intended use, climate conditions, and desired aesthetic. The alloy's composition contributes not only to the door's structural integrity but also influences its weight, finish, and overall performance.

Heat Treatment and Annealing:

Post-casting, the doors undergo heat treatment and annealing processes to enhance their mechanical properties. Heat treatment involves subjecting the cast aluminum to controlled heating and cooling cycles to achieve specific hardness and strength characteristics. Annealing, on the other hand, involves heating the material to relieve internal stresses and improve its overall machinability. These processes are critical in ensuring that the cast aluminum doors meet the required standards for durability and performance.

Machining and Finishing Touches:

Precision machining refines the cast aluminum doors, ensuring that they meet exacting specifications. Automated machining processes, guided by digital designs, remove excess material, fine-tune dimensions, and create openings for hardware components. The machining phase exemplifies the seamless integration of technology into the traditional craftsmanship of door manufacturing.

Following machining, the doors undergo a series of finishing touches. Surface treatments, such as powder coating or anodizing, enhance the doors' aesthetic appeal while providing additional protection against corrosion. Designers may collaborate with finishing specialists to achieve specific colors, textures, or patinas that complement the architectural context in which the doors will be installed.

Quality Control and Inspection:

The commitment to quality is a constant thread running through the entire process of Manufacturing Cast Aluminum Doors. Rigorous quality control measures, including visual inspections, dimensional checks, and material testing, are implemented at various stages of production. These measures ensure that each door meets or exceeds industry standards for strength, durability, and aesthetic precision.

Customization for Architectural Harmony:

One of the remarkable aspects of manufacturing cast aluminum doors is the potential for customization. Designers can work closely with manufacturers to create doors that harmonize with the architectural context of a building. Whether it's replicating historical patterns for a restoration project or crafting contemporary designs for a modern structure, the versatility of cast aluminum allows for tailored solutions that align with the vision of the architect.

Installation and Integration:

The journey of a cast aluminum door culminates in its installation, where the door becomes an integral part of the architectural ensemble. The precise measurements, flawless finish, and structural integrity achieved during the manufacturing process contribute to a smooth installation. Designers collaborate with installation teams to ensure that the doors seamlessly integrate into the architectural design, providing both functionality and visual coherence.

Sustainability Considerations:

In the contemporary design landscape, sustainability is a driving force in material choices and manufacturing processes. The inherent recyclability of aluminum makes cast aluminum doors an environmentally conscious choice. Designers can champion sustainable practices by selecting recycled aluminum alloys and advocating for energy-efficient casting techniques, further aligning the manufacturing process with eco-friendly principles.

Collaborative Partnerships in Design:

Manufacturing cast aluminum doors is a collaborative endeavor that requires effective partnerships between designers, craftsmen, engineers, and manufacturers. Clear communication, shared vision, and a deep understanding of both the artistic and technical aspects of the process are essential for success. Designers play a pivotal role in guiding the translation of design concepts into tangible, functional, and aesthetically pleasing architectural elements.

Conclusion:

In the intricate world of architectural design, the Manufacturing of Cast Aluminum Doors stands as a synthesis of artistry and engineering precision. From the meticulous crafting of patterns to the centuries-old technique of sand casting, each stage in the process contributes to the creation of doors that not only embody strength and durability but also exude elegance and sophistication. As designers, our appreciation for the subtle nuances and collaborative efforts involved in this manufacturing journey underscores the importance of cast aluminum doors as more than just functional elements—they are enduring expressions of architectural style and craftsmanship.

Español

Español Deutsch

Deutsch عربى

عربى