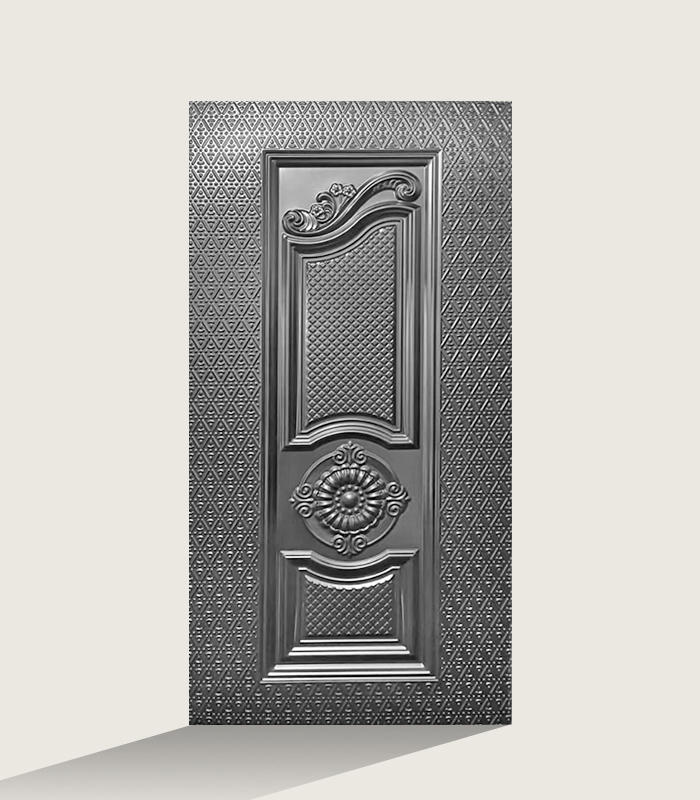

Sale Cheap Price Cast Aluminum Door Producer Manufacturer

In the realm of construction and architectural design, the manufacturing process of cast aluminum doors stands out as a testament to both tradition and innovation. Unlike traditional door materials such as wood or steel, cast aluminum doors undergo a unique process that combines craftsmanship with cutting-edge technology.

At the heart of the manufacturing process lies the raw material itself: aluminum. Cast aluminum, renowned for its durability, lightweight nature, and corrosion resistance, serves as the foundation for crafting doors that meet higher standards of quality and performance.

The journey of transforming raw aluminum into sleek and functional doors begins with meticulous preparation. The aluminum ingots are carefully inspected for impurities and then melted down in specialized furnaces to achieve the desired consistency and purity. This molten aluminum is then poured into molds specifically designed to create the intricate shapes and designs characteristic of cast aluminum doors.

Once the molten aluminum has been poured into the molds, it undergoes a cooling process that allows it to solidify and take on the desired form. This step requires precision timing and temperature control to ensure uniformity and structural integrity. Advanced casting techniques, including gravity casting and pressure casting, are employed to achieve the desired level of detail and finish.

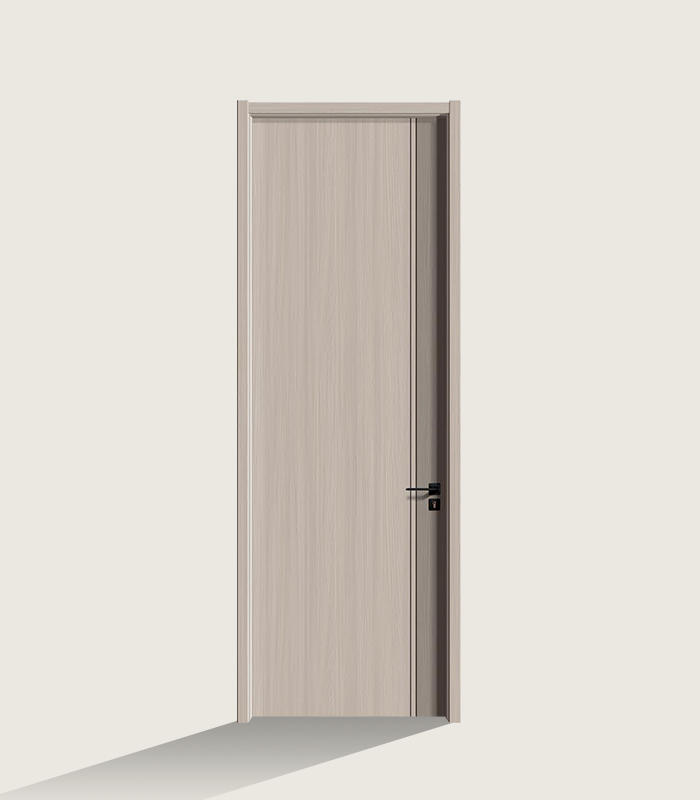

After the casting process is complete, the newly formed aluminum doors undergo a series of finishing touches to enhance their aesthetic appeal and functionality. This may involve machining, polishing, and surface treatments to achieve the desired texture, color, and sheen. Additionally, any necessary hardware components, such as hinges, handles, and locks, are meticulously installed to ensure seamless operation.

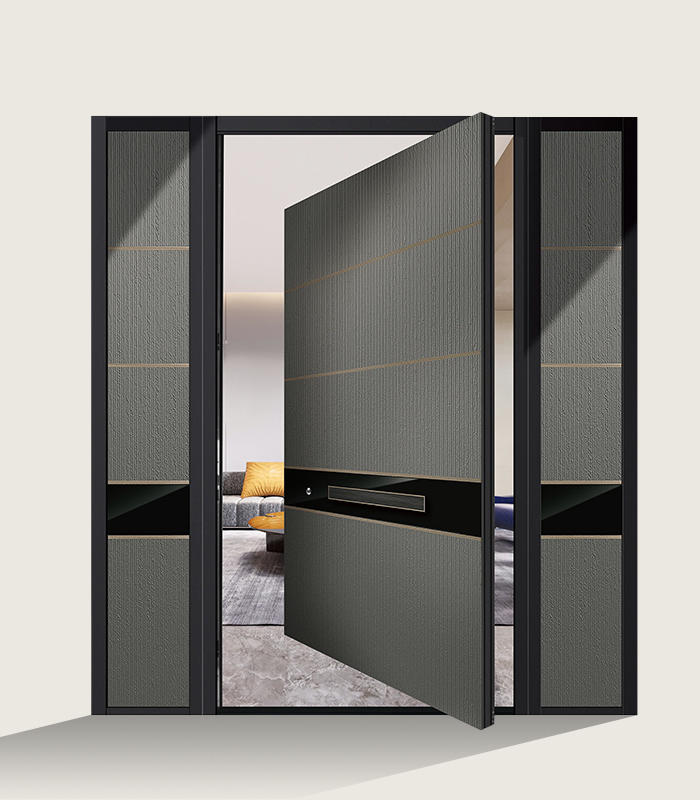

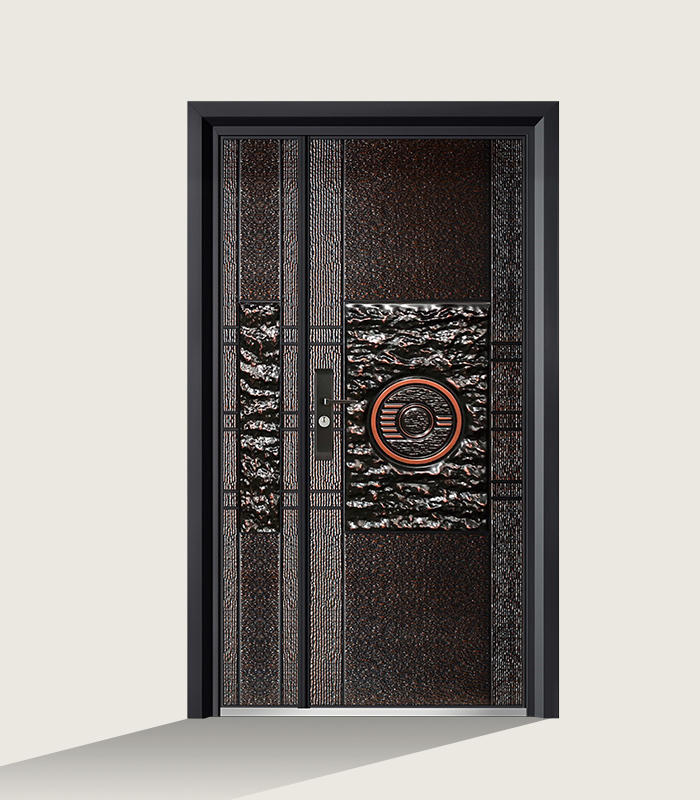

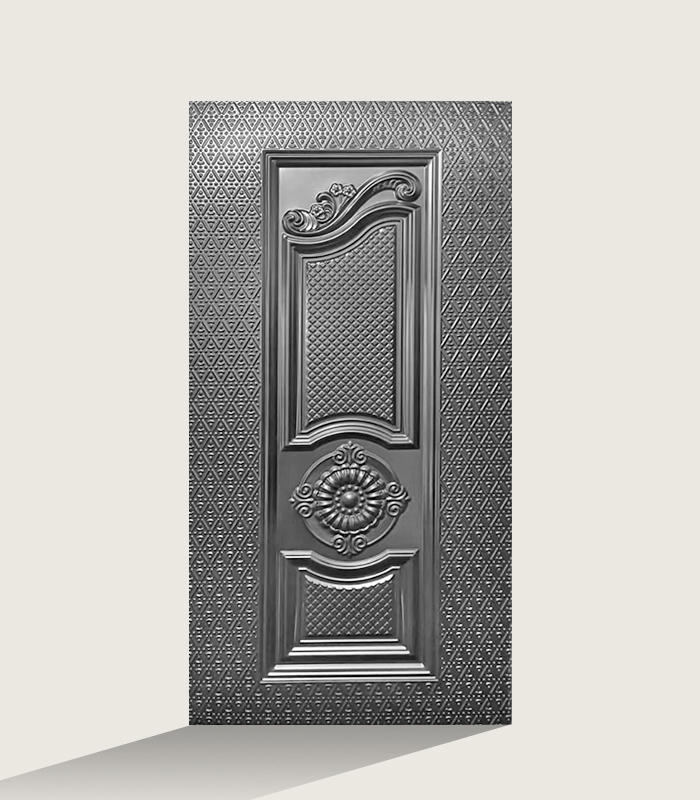

One of the key advantages of cast aluminum doors is their versatility in design. Unlike traditional materials that may be limited in shape and form, cast aluminum allows for intricate detailing and customization. Architects and designers can unleash their creativity, incorporating unique patterns, textures, and embellishments to complement any architectural style or aesthetic preference.

Cast aluminum doors offer good durability and longevity. Thanks to the inherent properties of aluminum, such as resistance to corrosion, rust, and environmental degradation, these doors are ideally suited for both interior and exterior applications. Whether enduring the harsh elements of outdoor exposure or the rigors of high-traffic commercial settings, cast aluminum doors stand the test of time with reduced maintenance.

In addition to their durability, cast aluminum doors are also highly sustainable. Aluminum is one of the most recyclable materials on the planet, with nearly 75% of all aluminum ever produced still in use today. By choosing cast aluminum doors, businesses and homeowners alike can contribute to reducing their environmental footprint and promoting a circular economy.

The manufacturing process of cast aluminum doors represents the perfect marriage of tradition and innovation. From the meticulous casting process to the final finishing touches, each step is guided by a commitment to good and quality craftsmanship. With their unparalleled durability, versatility, and sustainability, cast aluminum doors continue to redefine the standards of modern architectural design. Whether gracing the entrance of a luxury hotel or the storefront of a bustling retail space, cast aluminum doors make a lasting impression that transcends time and trends.

Español

Español Deutsch

Deutsch عربى

عربى